Brand: ATORN

Art.-no. 13397554

Manufacturer article no. 11946370

EAN 4050293349443

Application

For producing metric right-hand and left-hand threads on CNC machines, in steel, stainless steel, non-ferrous metals, cast iron and special alloy material groups up to a strength of 1500 N/mm².

Execution

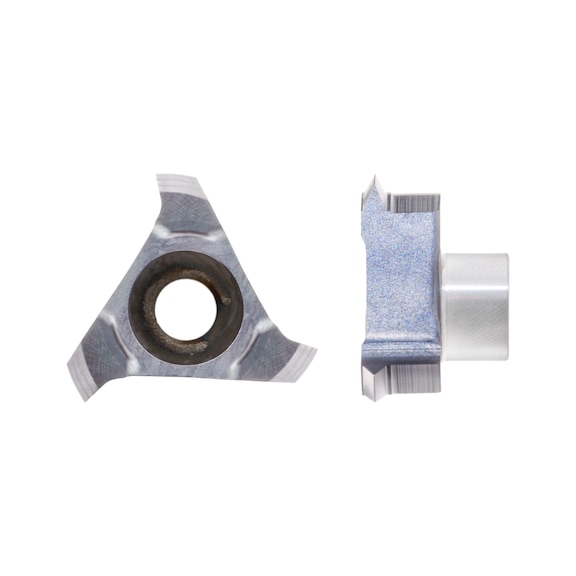

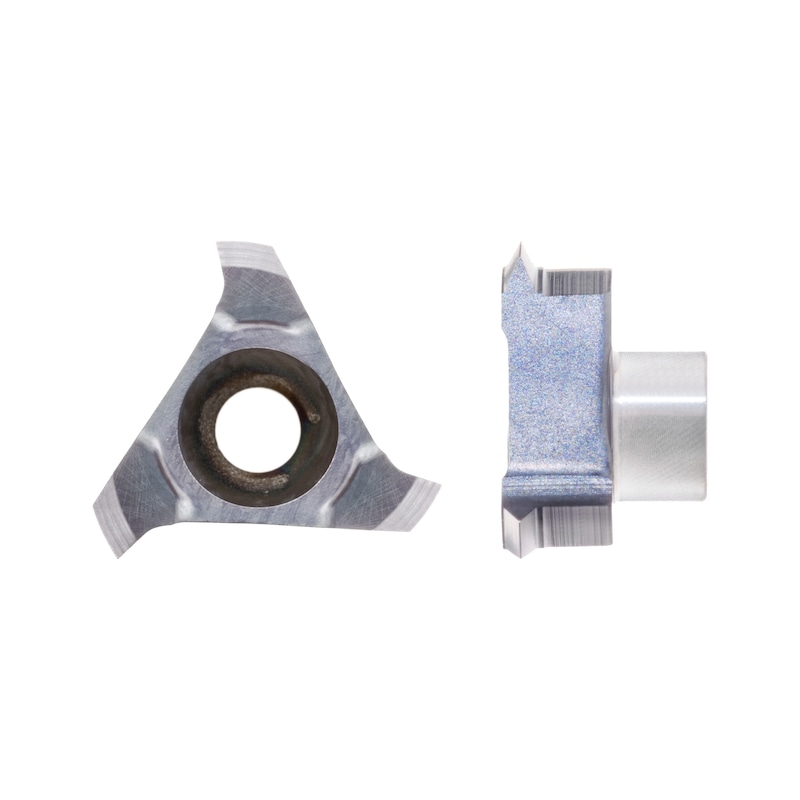

- Three-flute cutter in sub-profile design (indexable inserts type A25 in four-flute cutter design)

Advantage

- Innovative cutting geometry for excellent dimensional tolerance and process reliability

- High-quality cutting material and cutting edge finish

- Low tool costs due to high variability

Brand | ATORN |

EAN | 4050293349443 |

Manufacturer Part Number | 11946370 |

Indexable insert type | A12 |

Suitable for holder | A3 |

Min./max. pitch internal | 0.5-0.8 mm |

Min./max. pitch external | 0.4-0.8 mm |

Min./max. number of thread starts per inch internal | 56-28 |

Min./max. number of thread starts per inch external | 64-32 |

Cutting edge diameter | 12 mm |

Suitable for metric threads from | M13 |

Suitable for metric fine threads from | MF14 |

fz steel 1300 | 0.12 mm |

Product Group | 1FE |

Gross Weight | 0.006 kg |

| Material groups for cutting values | Description regarding DIN | Strength Class [N/mm²] | Material No. | Vc [m/min] | f [mm/r] with diameter | Suitability |

|---|---|---|---|---|---|---|

| 1.00 Steels | ||||||

| 1.01 Free machining steel | 9 S 20 | < 900 | 1.0711 | 60-120 | ⚫ | |

| 1.02 Structural steel | ST 37-2 | <500 | 1.0037 | 60-120 | ⚫ | |

| 1.03 Structural steel | ST 60-2 | > 500 | 1.7735 | 60-110 | ⚫ | |

| 1.04 Heat-treated steel | 42 CrMo 4 | <1000 | 1.7225 | 60-80 | ⚫ | |

| 1.05 Cast iron | GS-45 | <1000 | 1.0446 | 60-80 | ⚫ | |

| 1.06 Case-hardened steel | 16 MnCr 5 | <1200 | 1.7131 | 60-80 | ⚫ | |

| 1.07 Ferritic/martensitic stainless steel | X 10 Cr 13 | <1100 | 1.4006 | 80-100 | ⚫ | |

| 1.08 Heat-treated steel | 43 CrMo 4 | >1000 | 1.3563 | 50-80 | ⚫ | |

| 1.09 Nitriding steel | 31 CrMoV 9 | <1300 | 1.8519 | 60-90 | ⚫ | |

| 1.10 Tool steel | X 38 CrMoV 5 1 | <1300 | 1.2343 | 50-80 | ⚫ | |

| 2.00 Stainless steels | ||||||

| 2.01 Austenitic stainless steel | G-X 2 CrNiMo 18 15 | <1100 | 1.3953 | 60-90 | ⚫ | |

| 3.00 Non-ferrous metals | ||||||

| 3.01 Long-chipping aluminium | AI99.9 | <500 | 3.0305 | 100-200 | ⚫ | |

| 3.02 Short-chipping aluminium | G-AISi12 | <500 | 3.2581 | 60-140 | ⚫ | |

| 3.03 Copper alloy bronze, long-chipping | CuSn4 | <1200 | 2.1016 | 100-180 | ⚫ | |

| 3.04 Copper alloy bronze, short-chipping | CuNi12Zn24 | <850 | 2.0730 | 60-120 | ⚫ | |

| 3.05 Copper alloy brass, long-chipping | Cu Zn 20 | <600 | 2.0250 | 100-180 | ⚫ | |

| 3.07 Thermoplastic | Cu Zn 39 Pb 3 | <600 | 2.0381 | 60-120 | ⚫ | |

| 3.07 Thermoplastic | PVC, Acrylglas | <100 | 100-200 | ⚫ | ||

| 3.08 Duroplast | Bakelit, Melamin | <150 | 100-200 | ⚫ | ||

| 3.09 Fibre-reinforced plastics | CFK, GFK | <1500 | - | |||

| 3.10 Graphite | C8000 | <60 | - | |||

| 3.11 Composite materials | - | |||||

| 4.00 Cast metal | ||||||

| 4.01 Grey cast iron | GG10 | <260 HB | 0.6010 | 40-80 | ⚫ | |

| 4.02 Spheroidal graphite iron | GGG 40 | <310 HB | 0.7040 | 40-80 | ⚫ | |

| 4.03 Ductile iron | GTW-55 | <280 HB | 0.8055 | 40-80 | ⚫ | |

| 5.00 Special alloys | ||||||

| 5.01 Titanium alloy | TiAI5Sn2,5 | <1200 | 3.7115 | 20-40 | ⚫ | |

| 5.02 Nickel-based alloy | NiCr21Mo | <1400 | 2.4858 | 20-40 | ⚫ | |

| 5.03 Super alloys | X45CrSi 9 3 | <1400 | 1.4718 | 20-40 | ⚫ | |

| 6.00 Hard materials | ||||||

| 6.01 Hardened steel -55 HRC | x40CrMoV5-1 | -55HRC | 0.9620 | 50-70 | ⚫ | |

| 6.02 Hardened steel -65 HRC | 90MnCrV8 | <65HRC | 50-70 | |||